Successful sales meeting with representatives from all over the world

Representatives from all over the world met for the international sales meeting of Evosys Laser GmbH in Erlangen this year. After two years of COVID-19, the meeting took place in the form of a hybrid event, so that the participants were briefed about the latest trends in laser plastic welding both on site and in

Evosys Laser at trade fairs in autumn

Evosys Laser continues to be present at trade shows. In autumn, we will be exhibiting at the VDI conference in Wiesbaden, Motek in Stuttgart, izb in Wolfsburg and K in Düsseldorf. All fairs are well-known industry events and suitable platforms to present our EVOSYS systems and solutions for joining plastic parts. We look forward to

Special award for EVOSYS

Evosys Laser was awarded the prize “BAYERNS BEST 50”. The award is presented annually by the Bavarian Ministry of Economic Affairs, Regional Development and Energy to the 50 fastest-growing mid-tier businesses in Bavaria. The aim of the business award is to promote entrepreneurial responsibility and thus create opportunities for growth and employment. Almost 7,000 companies

Lots of new things at our booth at the K show 2022 !

EvoWeld Mini: The new compact machine for laser welding of plastics Our preparations for the fall trade show are already in full swing. Because at this year’s K 2022 trade show, the global industry highlight for the plastics and rubber industry, we are happy to showing you our innovations. First and foremost, the EvoWeld Mini,

Communication, ergonomics and better acoustics for the EVOSYS team

In the first months of the Corona pandemic, some people initially thought that the “home office” and videoconferencing were the solutions to all the questions surrounding a contemporary workplace. In the initial euphoria, the classic workplace in the office was already being replaced. But with the duration of the pandemic, employees and companies have had

Meet Evosys Laser at Trade Shows in June

After successful participations at industry events such as Medtec Live with T4M or KUTENO, Evosys Laser continues to be present at trade fairs in June. LASYS in Stuttgart and automatica in Munich each offer a suitable platform for our EVOSYS systems and solutions for joining plastic parts. We look forward to welcoming you there in

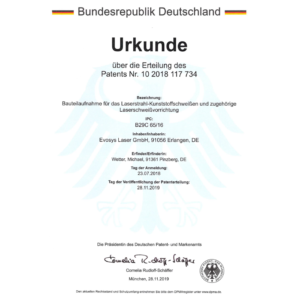

Securing innovations sustainably through patents

Innovative developments around laser material processing improve productivity and quality and thus customer benefits. However, they are usually associated with a high level of financial and personnel expenditure, which is incurred well before they are marketed. To ensure that these investments are returned and thus open up the possibilities for future developments, the EVOSYS Group

Evosys Laser GmbH with extremely successful year 2021 and very good start to fiscal year 2022

The EVOSYS Group can look back on the most successful financial year in the company’s history, despite the Corona pandemic and the worldwide supply bottlenecks. After consolidating the figures in the Group, it is clear that our expectations were exceeded and the future trend is right. Although the pandemic and the worldwide supply bottlenecks reduced

SPICA Plastics – Thermographic inspection system with optical excitation by INTEGO GmbH

Advantages of SPICA PlasticsSPICA Plastics enables non-destructive testing without surface treatment, is fast and can be automated relatively easily. It reliably provides objective inspection results and also allows the defect size to be determined. This makes it very suitable for fully automated testing systems for 100% inspection of components in the industrial production line. Functionality

New EVOSYS representatives for Poland and Turkey

TRUmachines (https://trumachines.com) manufactures specialized machines, workstations and tools for the fields of automation technology, materials handling, CNC machining, PLC programming and 3D modeling and converts them into modern, user-friendly machines. In addition, the experienced family business designs complete production lines and production processes. We have been working successfully with our contact person, Mr. Tomasz Uzar,