A successful cooperation gets a new name

For years, Intego has been successfully produced infrared inspection systems for radial, flat or other infrared-transparent plastic parts. These have always ideally complemented the laser plastic welding technology of our partner company Evosys. Evosys’ customers appreciate the universal application possibilities of the inspection systems, both for process optimisation in the laboratory, for determining the transmission before the welding process, and for inspecting the weld seam itself. Due to the close proximity to the customer, the inspection systems are therefore mainly sold by Evosys, while the technical realisation, in particular also in the case of customer-specific adaptations, continues to lie with Intego.

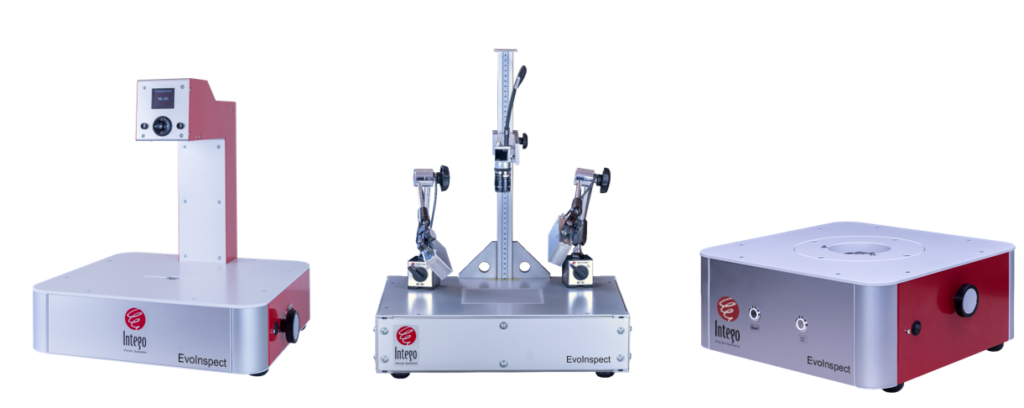

To reflect this successful cooperation, the device series has now been given a new name: EvoInspect.

EvoInspect Radial, Planar and Vision

The EvoInspect Planar and the EvoInspect Radial enable material characterisation before the welding process for flat or radially symmetrical components by determining the transmission of the laser-transparent weld partner. In recent months, the electronics of both systems have been further advanced with the aim of increasing the already high measurement accuracy even more. Both systems can be used as stand-alone systems for accompanying quality control, as well as integrated into the production for online monitoring of the production process.

The EvoInspect Vision is universally applicable for the qualitative inspection of plastics that are optically transparent in the wavelength range 750 nm – 1500 nm, or for the inspection of weld seams after their welding process. The adjustable IR illumination enables fast and easy inspection of a wide range of components. Due to constructive customer feedback, the software has also been improved with sophisticated automatic evaluation options, which are now available to our customers.

Interested parties are welcome to convince themselves of the possibilities of our systems at an on-site appointment at Intego GmbH in Erlangen using their own components. You can also find further information at www.intego.de, or our profile on Linkedin.

Contact:

Intego GmbH

Dr. Simone Gaffling

Henri-Dunant-Str. 8

91058 Erlangen