The Bavarian Innovation Award was presented to Evosys Laser. The award is given every two years by the Bavarian State Ministry of Economic Affairs, Regional Development and Energy, the Association of Bavarian Chambers of Industry and Commerce and the Association of Bavarian Chambers of Crafts. The jury was impressed by the innovative and patented AQW process. The aim of the award is to honor particularly successful innovations by Bavarian companies.

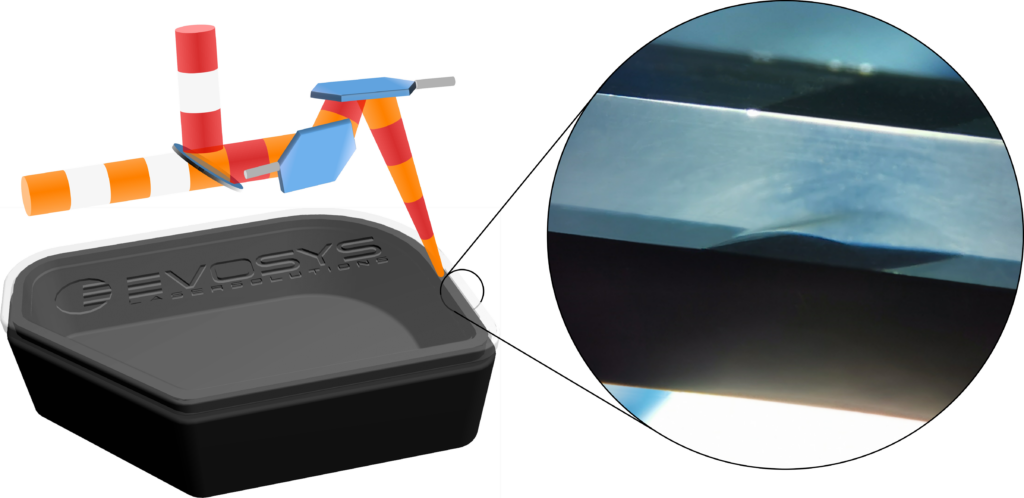

Among nearly 200 top-class innovations, the jury found the patented AQW laser welding process from Evosys Laser GmbH particularly worthy of the Bavarian Innovation Award. The new variant of laser welding of plastics combines two laser beam sources and wavelengths. This approach aims in particular to significantly reduce welding times and extend the process window in quasi-simultaneous welding. By using two different wavelengths, the input of beam energy and heat can be better controlled.

An independent jury had selected the winners in advance, and the award ceremony took place on Monday, November 21 at the Swabian Chamber of Industry and Commerce in Augsburg. The Bavarian Minister of Economic Affairs, Mr. Hubert Aiwanger, congratulated the winners in person.

Numerous awards

Evosys Laser has already received several founder awards and has been awarded the “TOP 100 Innovations Champion” Award in 2020. This year, Evosys Laser GmbH has already received the “BAYERNS BEST 50” award. It is awarded annually by the Bavarian State Ministry of Economic Affairs, Regional Development and Energy to the 50 fastest-growing medium-sized companies in Bavaria.

An industry award is also still to be presented this year. The trade journal MM MaschinenMarkt has selected Evosys Laser, also with the AQW process, as a contender for the Best of Industry Award in the “Plastics Technology” category. This industry award promotes innovative solutions from technically oriented companies.

The patented AQW process (Advanced Quasi-Simultaneous Welding) enables to perform the welding process even more reliably and quickly. Tests with the AQW process show that a significant improvement in process time and weld strength is possible compared to the standard process with only one laser source. Due to the wavelength of the secondary laser radiation, more energy is absorbed in the transmissive joining partner throughout the process. This increases the plasticized and melted material volume of the laser-transparent part. By switching between the two beams, the total amount of energy introduced into the joining area can be increased without damaging the absorbing layer or the transparent layer. This results in faster plasticization and thus a faster and more efficient welding process.

For more information on the prizes and awards, visit:

Innovationspreis Bayern

BAYERNS BEST 50

Best of Industry Award

Do you have any further questions about the company or would you like a personal meeting? Then please feel free to contact us at +49 9131 – 4088 – 1050.

Previous Article