Evosys Laser was awarded the prize “BAYERNS BEST 50”. The award is presented annually by the Bavarian Ministry of Economic Affairs, Regional Development and Energy to the 50 fastest-growing mid-tier businesses in Bavaria. The aim of the business award is to promote entrepreneurial responsibility and thus create opportunities for growth and employment.

Almost 7,000 companies were invited to submit their applications. The “BAYERNS BEST 50” award is given to particularly fast-growing medium-sized companies that have been able to increase the number of their employees and their sales above average in recent years. In the case of EVOSYS, this is true despite the challenging general conditions of recent times.

An independent jury had determined the award winners in advance. The award ceremony took place on Tuesday, July 26 at Schleißheim Castle in Munich. The Bavarian Minister of Economic Affairs, Hubert Aiwanger, congratulated the winners in person.

Evosys Laser GmbH has already received several start-up awards and was honored with the ‘TOP 100 Innovations Champion’ Award in 2020. Another highly sought after business prize this year is still pending, as the company has been nominated for the “Großer Preis des Mittelstandes 2022”. This business prize does not evaluate figures, innovations or jobs alone, but the company as a whole and in its complex role in society. The finalists will be announced at a gala evening in Würzburg in September.

Another industry award is still to be announced this year. The trade journal MM MaschinenMarkt has selected Evosys Laser and its AQW process as a contender for the Best of Industry Award in the “Plastics Technology” category. This industry award promotes innovative solutions from technically oriented companies.

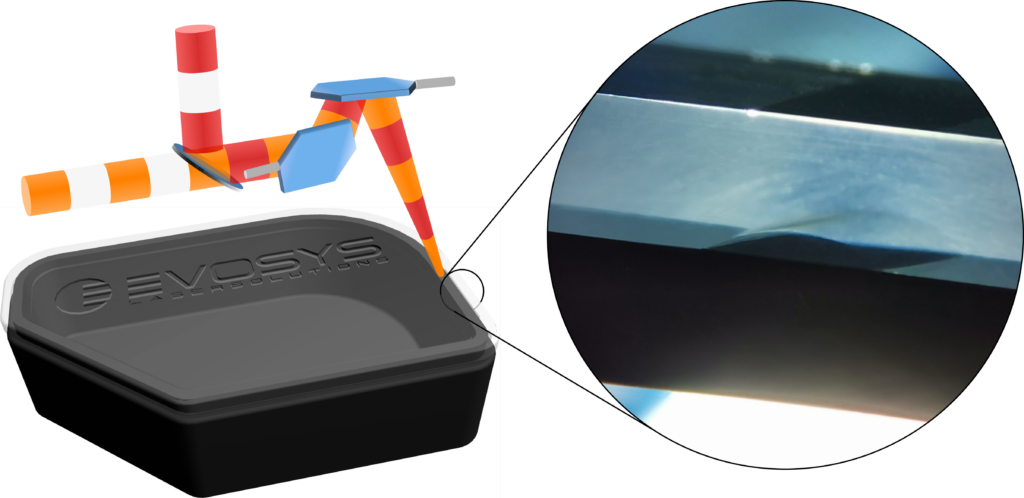

The patented AQW process (Advanced Quasi-Simultaneous Welding) is a new variant of laser welding of plastics. It combines two laser beam sources and wavelengths. The focus is on reducing welding times in quasi-simultaneous welding and expanding the process window. By using two different wavelengths, the input of beam energy and heat can be better controlled. It leads to a considerable increase in efficiency, and selected plastics can be processed even more economically.

For more information about the prizes and awards, visit:

https://www.stmwi.bayern.de/wettbewerbe/bayerns-best-50

https://www.mittelstandspreis.com

https://www.bestofindustry.de

Do you have any further questions about the company or would you like a personal meeting? Then please feel free to contact us at +49 9131 – 4088 – 1050.

Previous Article