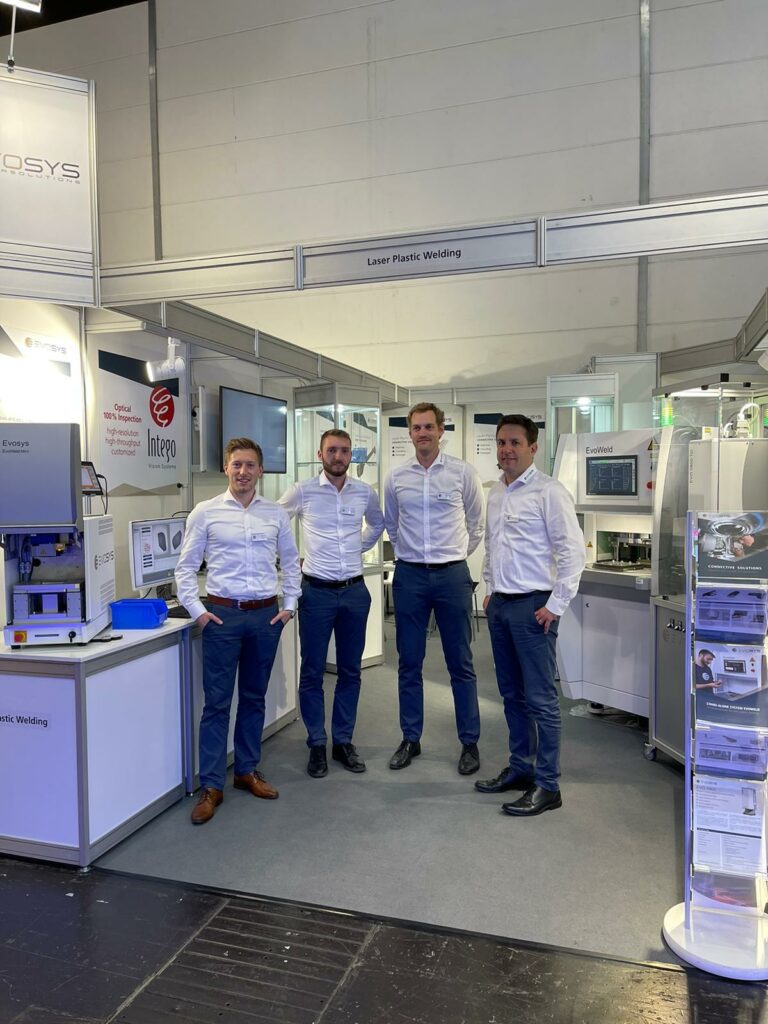

After a long period of corona-related restrictions, EVOSYS was again represented under almost normal conditions at the K trade fair this year. There, our team was able to present and demonstrate live a whole range of new and innovative EVOSYS products. In addition to the efficient EvoWeld stand-alone system for quasi-simultaneous welding, this year the handy table-top system EvoWeld Mini completed our family of complete systems.

With a coherent, ergonomic and economical overall concept, the EvoWeld Mini was developed especially with a focus on making laser plastic welding attractive for smaller quantities or laboratory operation. The interested public was able to try out the system for themselves and see the simple and well thought-out operating concepts of both systems during live welds.

The EVO 0800-TD process module, which was also premiered alongside the EVO 0550 and EVO 0750 laser modules already available, was also very well received. As a slim welding system with customized laser optics and integrated clamping unit, it represents a highly flexible integration solution for quasi-simultaneous welding with low space requirements.

Last but not least, the visitors were able to get an idea of the optical inspection systems that EVOSYS offers with its partner, Intego GmbH, and is constantly developing further. The highlight here was a new version of the Vision camera system, which enables direct optical evaluation of the weld seam and has new features such as transmission detection along an entire weld seam contour. This system makes a significant contribution to ensuring the quality of the weld seam and can be used both in-process and integrated for inline monitoring.

Our trade fair team was kept well on its toes throughout, and overall we can look back on a successful and exciting K trade fair. We would like to thank our long-standing customers as well as new prospects for their lively interest, which made this successful event possible! We are looking forward to the upcoming projects!

Whether as a simple stand-alone system, integration solution or complex special system, all EVOSYS machines are designed for use in a 24/7 production and fit into any application environment. Our team collected decades of experience in mechanical engineering and laser technology. We guarantee high flexibility and productivity of your welding systems. With our many years of experience, we know what matters when it comes to joining plastic parts.

Our experts will support you right from the early stages of your project. Ask us for a personal consultation. We will take up your individual needs and show you solutions. You can reach us by phone at +49 9131 – 4088 – 1029 (Mr. Holger Aldebert) or by e-mail at sales@evosys-laser.com.