A special form of contour welding is the variant for processing radially symmetrical assemblies. An essential difference of this special form to the other process variants of laser welding of plastics is the introduction of the joining pressure into the joining zone. Due to the radially symmetrical structure of the joining assembly in the area of the weld, it is possible to work via an interference fit and thus achieve the joining pressure required for heat conduction. As a result, clamping technology in contact with the component can generally be dispensed with.

The positive consequences are economical system setups and short overall process times. Since component tolerances are very important due to the use of interference fit, mastery of the pre-processes is of particular significance.

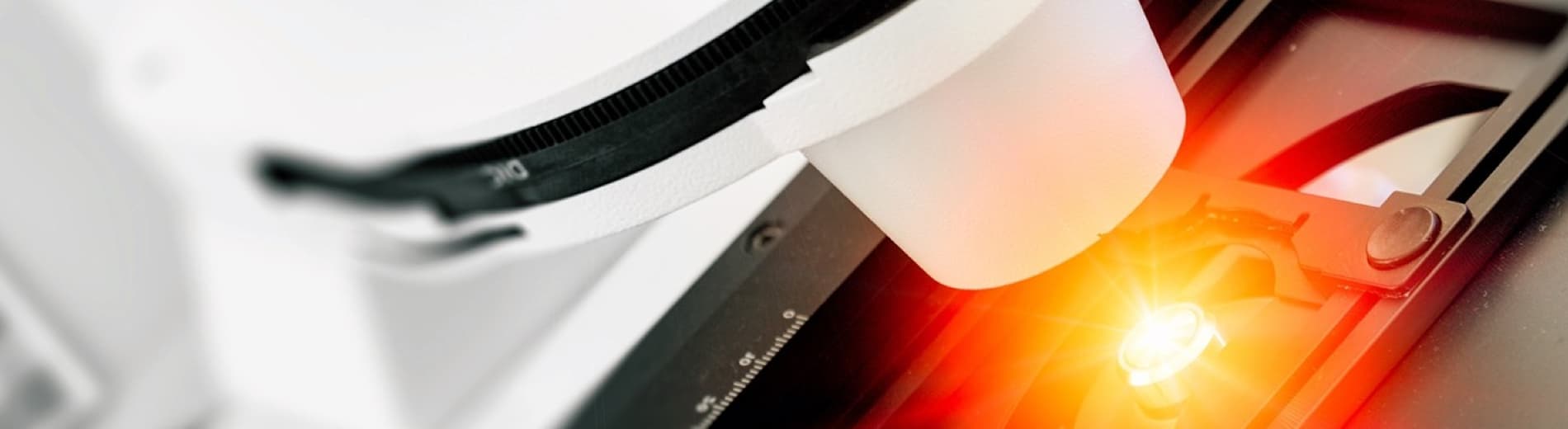

Three types of the process are distinguished: laser fixed and the component moves; component fixed and the laser rotates around the component; component fixed and the laser is reflected by mirrors onto the component and rotates around the component. All three variations are illustrated in our animation.

Radial plastic welding can be very well controlled inline with the appropriate process monitoring and process software.