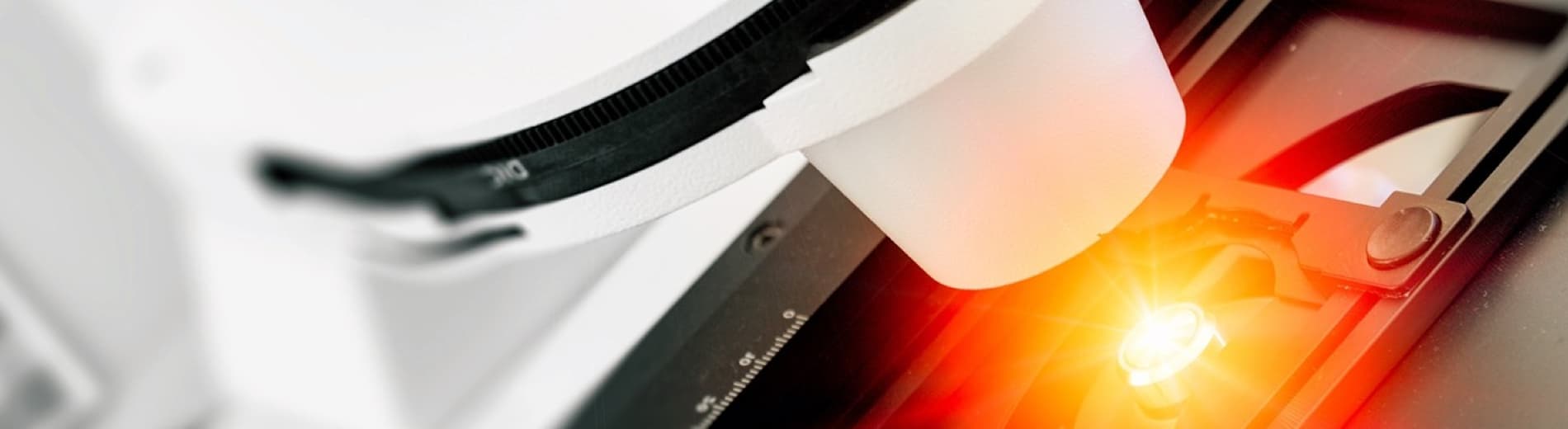

Quasi-simultaneous welding is a frequently used variant of laser plastic welding. The weld seam is traversed several times at high speed with a focused laser beam. In this process, all areas of the weld seam are heated and melted almost simultaneously (i.e. quasi-simultaneously). Our animation explains this process in a simple way.

A robust and extremely economical process with outstanding process reliability

Due to the simultaneous melting of the entire weld contour and the clamping force applied by the clamping technology, both joining partners move towards each other, and melt is expelled laterally at the weld seam. This joining path can compensate for component unevenness, and measurement of this movement is also suitable for process control.

Strong for many housings and flat components

Quasi-simultaneous welding is most often chosen for sealing all types of housings and sensors. Flat components such as electronic housings in the automotive or consumer sectors can also be joined quickly and precisely in this way.